Rubber Sidewalks

Rubberway Rubber Sidewalk is a flexible, porous rubber pavement system that provides a sustainable, environmentally friendly solution to cracked sidewalks. Designed to replicate the look of concrete, rubber sidewalks have a number of advantages over traditional concrete sidewalks.

Rubber Sidewalks are Porous

Rubberway rubber sidewalks are porous, providing rapid, even drainage and filtration for stormwater management. This porosity also encourages deep rooting of trees, reducing root heave and associated sidewalk cracking.

Rubber Sidewalks are Flexible

Rubber sidewalks are also flexible which virtually eliminates cracking with movement of understrata and the associated trip hazards and liabilities.

Rubber Sidewalks Utilize Recycled Tire Rubber

These porous rubber sidewalks utilize recycled tire rubber to create a flexible, safe, non-slip surface. Post-consumer recycled tire rubber that is free of lead and heavy metals make up the base layer of the rubber sidewalk system. This diverts tires from landfills and reduces the need for virgin materials.

A Solution to Cracked City Sidewalks

Rubberway Sidewalks are the twenty-first-century green building solution for modern sidewalk infrastructure. They are a long lasting, low maintenance, safe, ergonomic, and non-slip choice for replacing cracked city sidewalks.

The Rubberway Rubber Sidewalk System

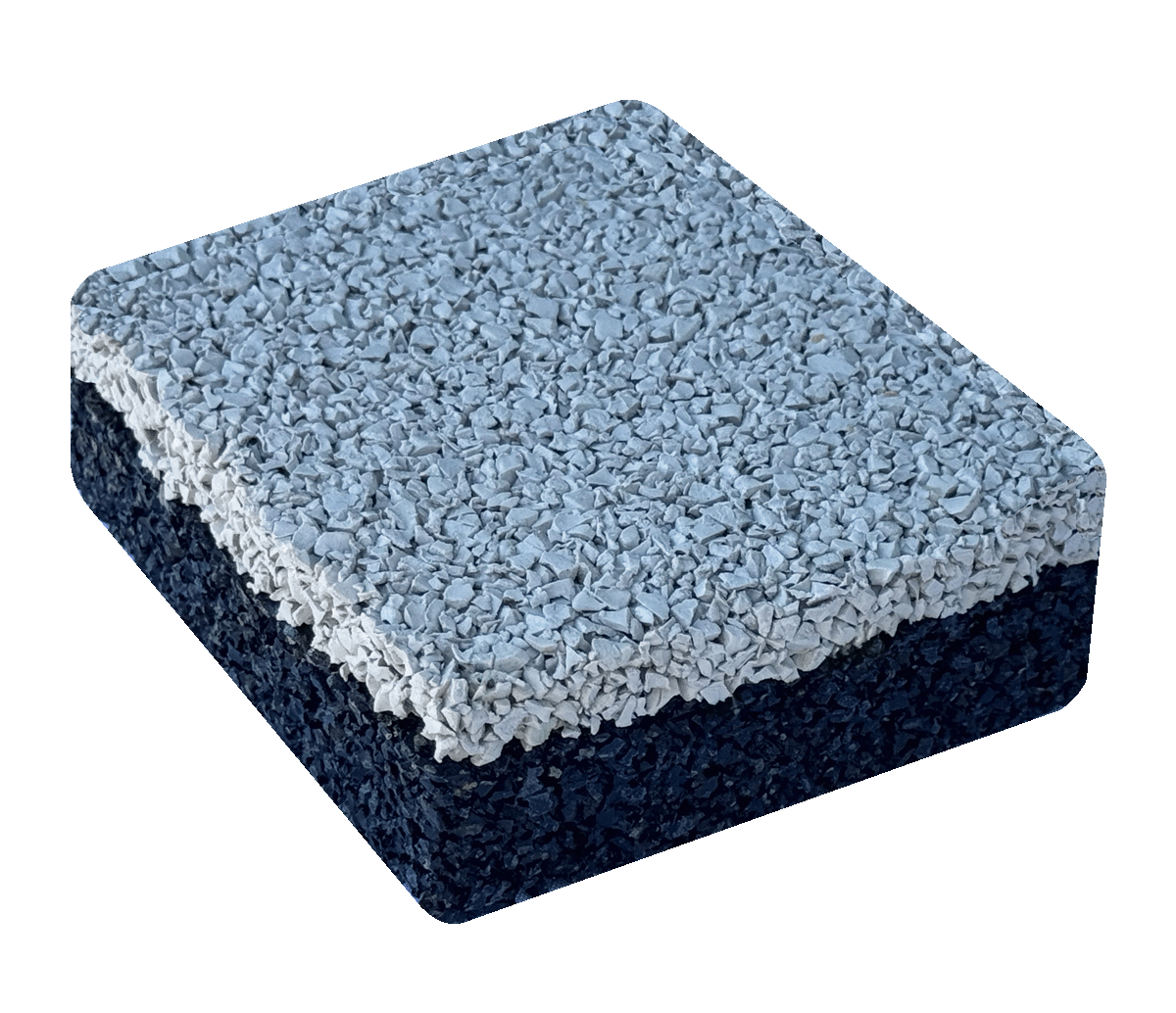

Rubberway Sidewalk is a patented, two-layer system. The base layer, fabricated from recycled rubber tires, is topped with a colored pure virgin rubber compound with UV resistance allowing for custom design options with a variety of colors to choose from.

Wear Layer: EPDM virgin colored rubber

Base Layer: 100% recycled crumb rubber

Sub-Base: Class two permeable road-base, concrete, or asphalt

Sub-base preparations vary by region. The base layer is specified at a 1 - 1 1/2" thickness while the colored wear layer (top layer) is specified at a 1/2" thickness. Edging can be concrete, steel, or recycled plastic lumber board. For each layer, the rubber granules are mixed with our proprietary binder, poured, and troweled evenly, and allowed to cure for up to twenty-four hours. A variety of colors are available for the wear layer, such as gray, beige, tan, terracotta red, and more.

Rubberway Sidewalk can be designed to curve around corners, down slopes, and can be installed directly over tree roots without damaging them or hindering growth.

Why Choose Rubberway Sidewalks?

Rubberway Sidewalks provide a superior, cost-effective, environmentally friendly alternative to asphalt, concrete, and preformed pavers. This pervious rubber sidewalks system offers diverse solutions to challenges related to construction and pavement infrastructure such as cracked sidewalks and root heave.

City and public works departments are constantly faced with the public safety concerns and financial burdens posed by sidewalks damaged by tree roots, freeze-thaw, and vehicular traffic. Rubberway Sidewalks were designed with these issues in mind and not only reduce root heave and cracking, but also provide filtration and stormwater management. Rubberway Sidewalks are also non-slip in both wet and dry conditions and are resilient and ergonomic for pedestrian use.

Rubberway Sidewalks are a long lasting, low maintenance replacement for cracked sidewalks and for new sidewalk installation.

Suggested Rubber Sidewalk Applications:

- Cracked sidewalk replacement

- New sidewalk installation

- City sidewalks

- New sidewalks in urban developments

- Park trails and pathways

- Stormwater management

- Corporate health and wellness

Rubberway Rubber Sidewalk Installation Video - Click Above to View

-

Recommended Applications

-

Related Products

-

Project Examples